O&M simulation logic

O&M uses a unique simulation logic to model the scheduled and corrective maintenance tasks you configure in your cases.

Below, you can find a mapping for the simulation flow from failure/ work order creation to completion. Agent (i.e., logistic, asset, and personnel) behavior is described, with a focus on assumptions that the Shoresim model makes.

Asset statuses and maintenance tasks

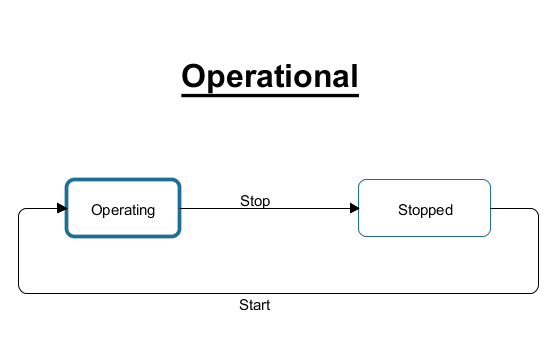

The first statechart illustrates possible WTG statuses:

- Operating: the WTG is working and generating energy.

- Stopped: the WTG is down due to weather conditions, failure, or scheduled maintenance.

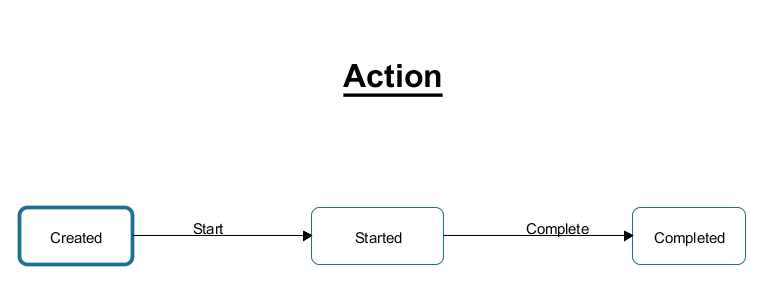

The second statechart shows the way in which work orders require action.

When a work order is created, it means that some maintenance or repair work is required on a WTG. The diagram illustrates how a work order progresses, from its creation to its completion.

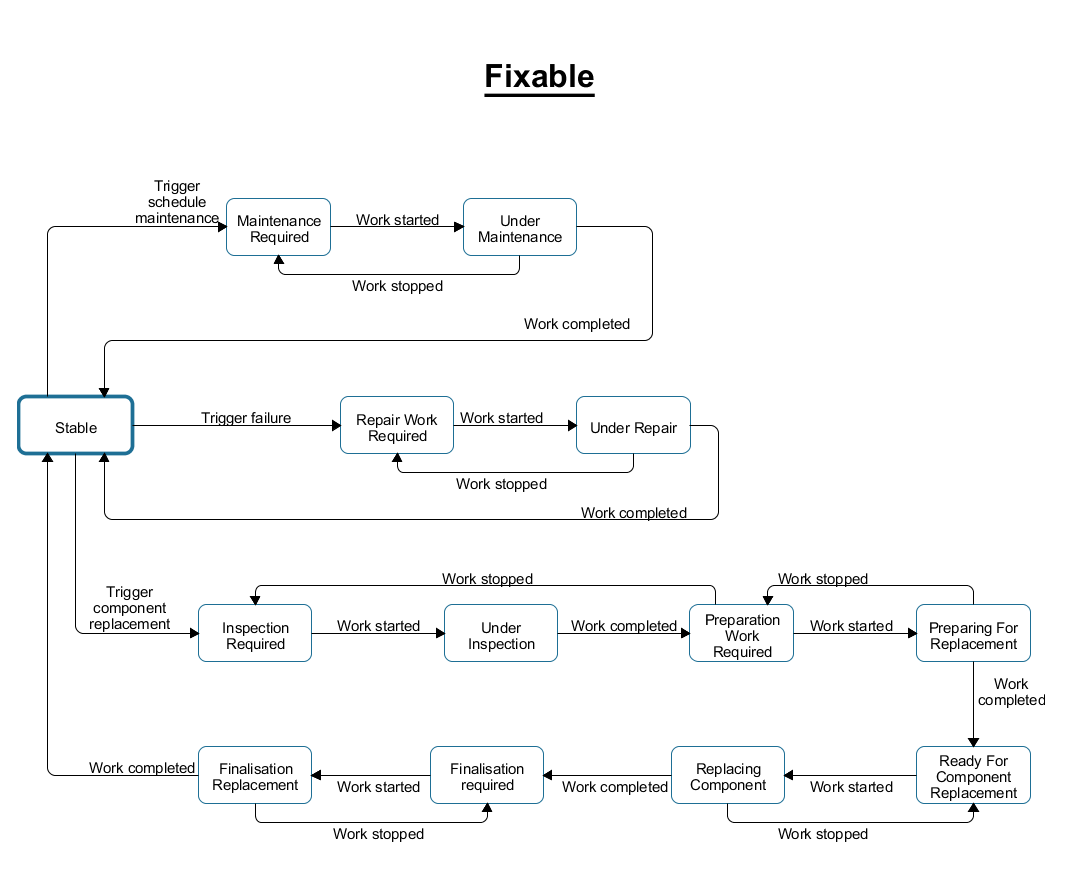

Scheduled maintenance, corrective maintenance, and component replacements

The Fixable statechart illustrates the possible failure states of an asset (scheduled maintenance, corrective maintenance (repair) and replacement tasks) and the work process to return them to an operational (stable) status.

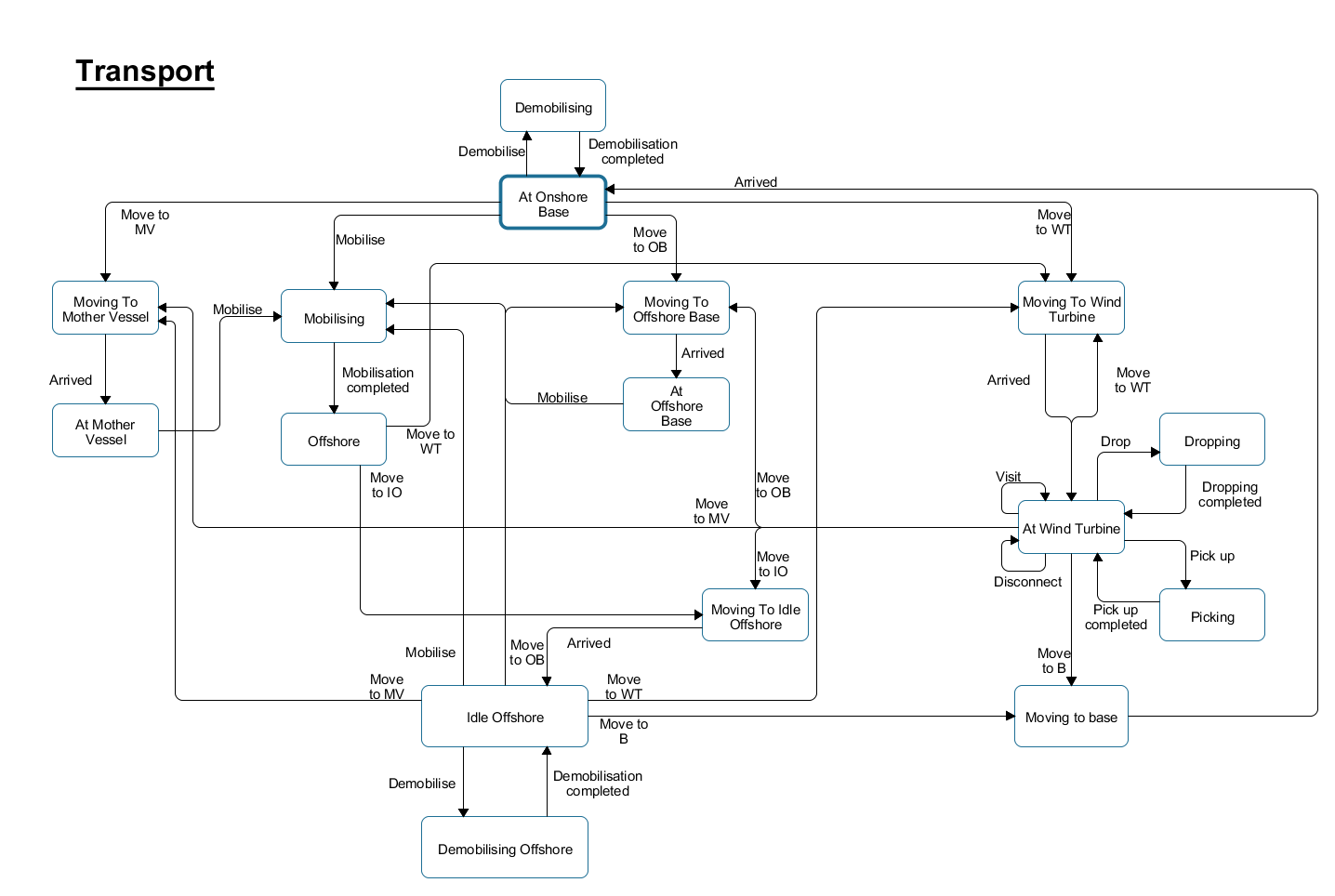

Logistics (CTV, SOV, Heli, towing vessel)

The Transport diagram shows the behaviour of different logistics. It represents a common pattern throughout the whole operational period of the wind farm.

Work orders for logistics

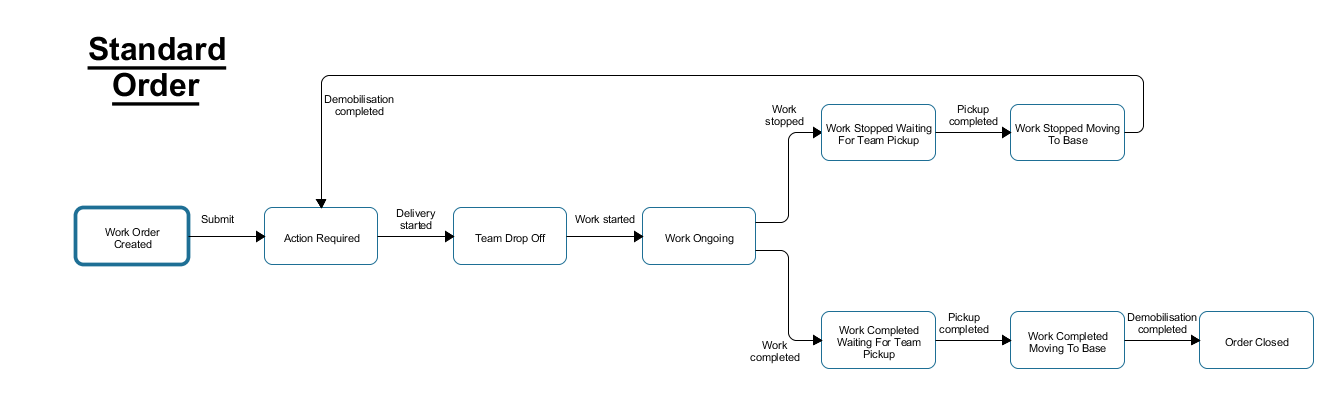

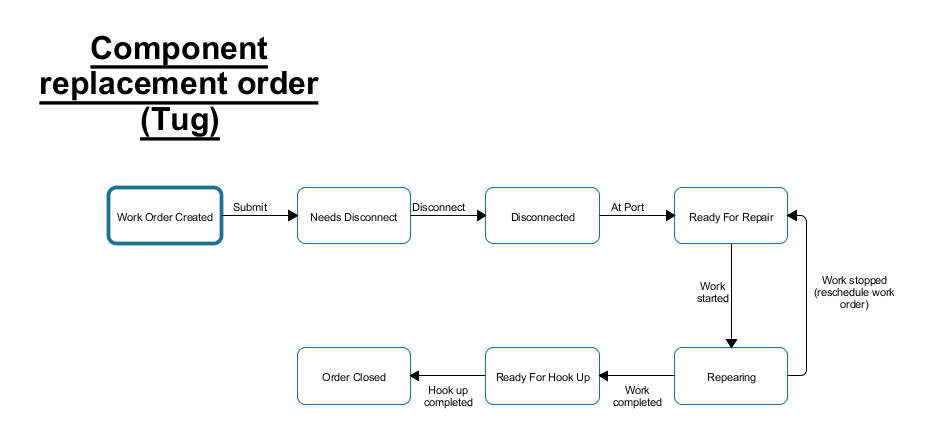

There are 3 types of work orders for logistics:

- Standard order

- Component replacement order (HLV)

- Component replacement order (towing vessel)

The Standard order diagram illustrates the different states when a work order is created for a scheduled or corrective maintenance task that doesn't use an HLV or a towing vessel.

When a component replacement order is assigned to an HLV, the logistic will follow the process as shown in the HLV diagram.

The final diagram illustrates the states when a component replacement is assigned to a towing vessel.

HLV

This is the process for an HLV with multiple work orders and a defined work order capacity:

- Logistic chartered: wait until the charter lead time expires.

- Check if it is time to schedule the logistic.

- Is it above the minimum used capacity?

- Has the longest waiting time among the assigned work orders expired?

- Schedule the logistic's mobilizing, preparing transit, transit to the first asset, and jacking up steps.

- Schedule work on the asset, jacking down, and the next transit steps.

- The next transit is either to the next assigned work order, then jacking up; or transit back to port, then demobilizing.

- This is repeated until there are no more assigned work orders and the logistic is back at port.

- The charter period ends and the logistic becomes available for charter when the next failure occurs.

Work orders

This is the process for schedulding a work order assigned to an HLV:

- Create a work order requiring an HLV.

- Assign the work order to a HLV.

- Check if there is a logistic chartered that has not been scheduled for going offshore yet and has capacity for another work order.

- If a logistic is not chartered and available, charter a new logistic.

- Perform the work when the HLV arrives at the work order location.

- Close the work order.

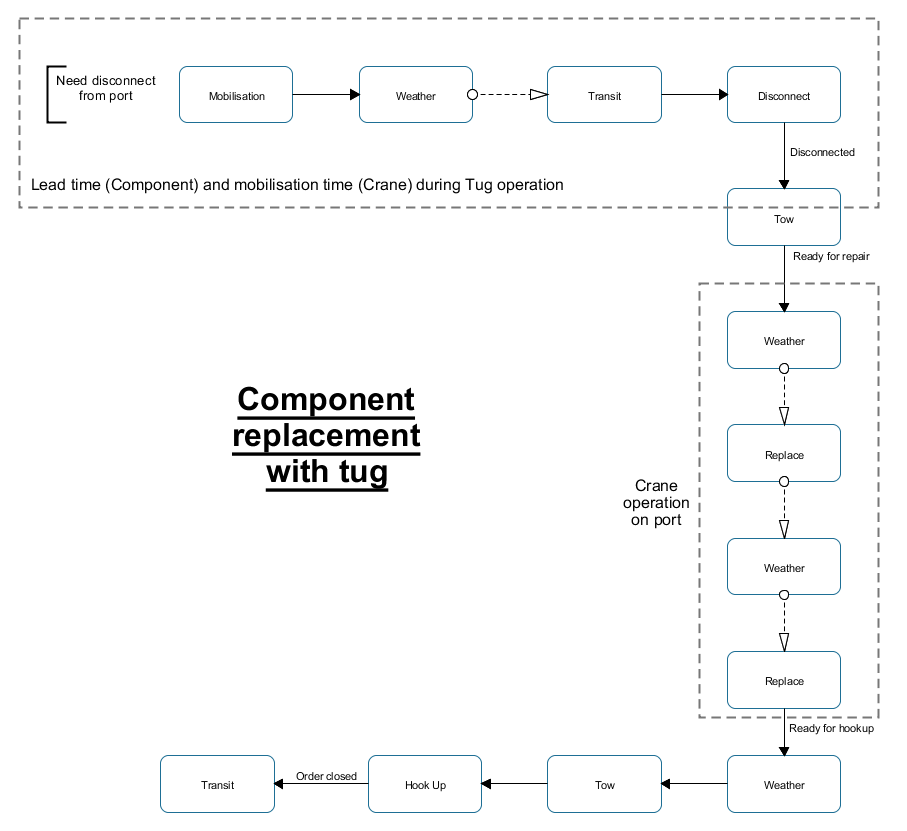

Towing vessel

The state chart below shows the component, crane, and towing vessel involvement in a component replacement order using a towing vessel.

While the towing vessel is on the way to the wind farm, the crane starts mobilizing towards the port, and the component lead time starts to count down. Once the component reaches the shore, it is fixed on the port by the crane and taken back to the offshore wind turbine by the towing vessel.

Crane

The crane is used to fix components that are taken to the port. Below, the process diagram showed presents all states a crane goes through when operating.